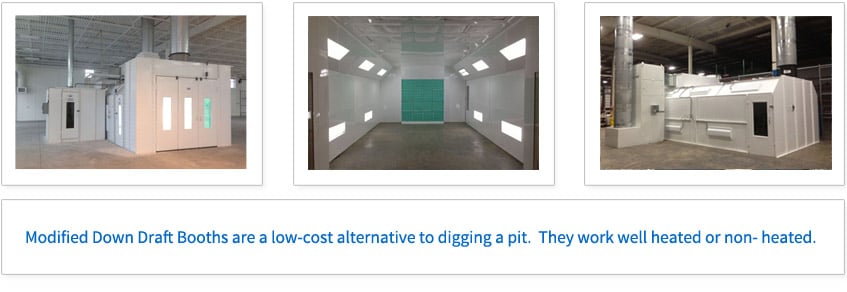

Modified Downdraft Paint Booths

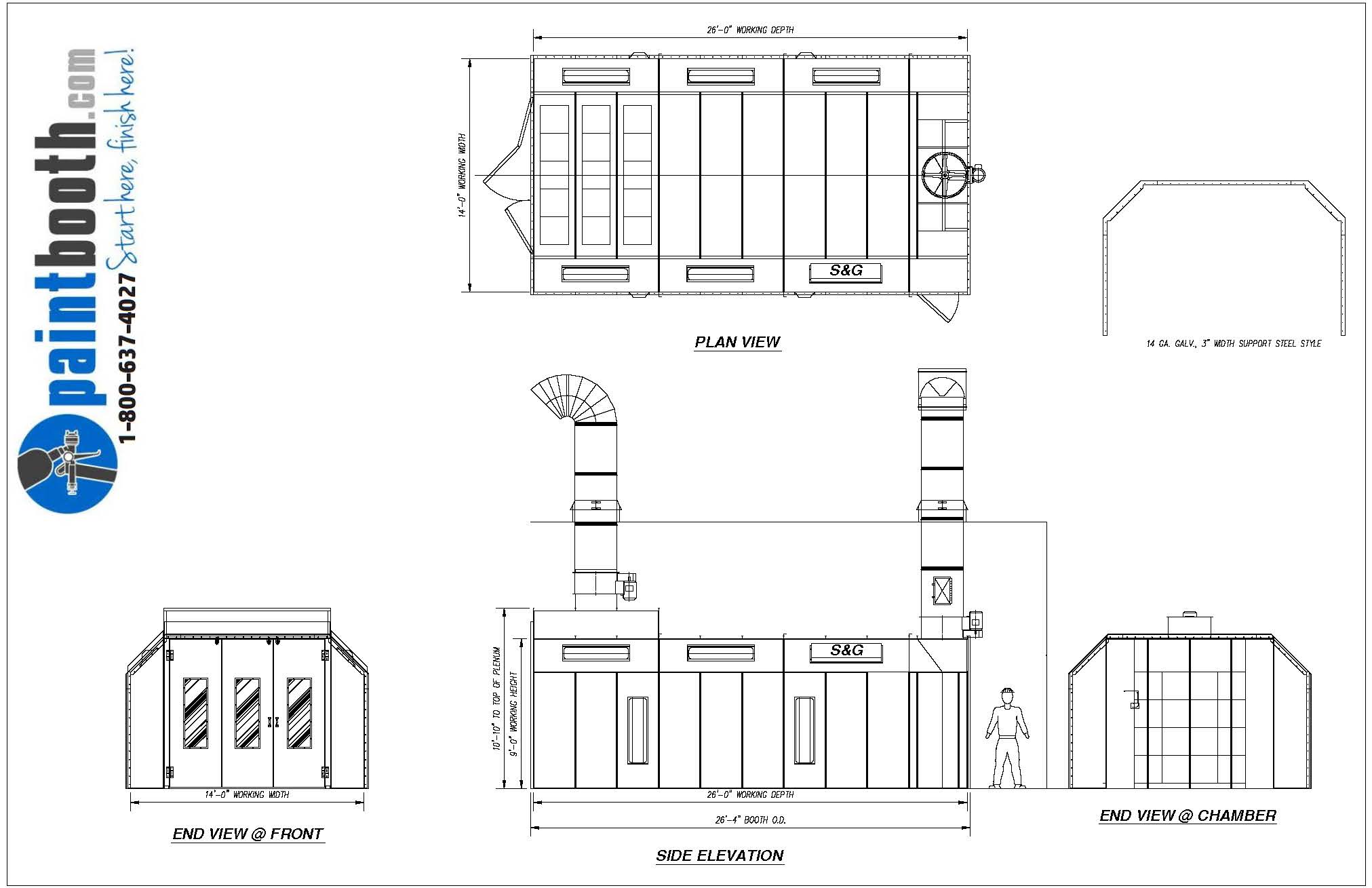

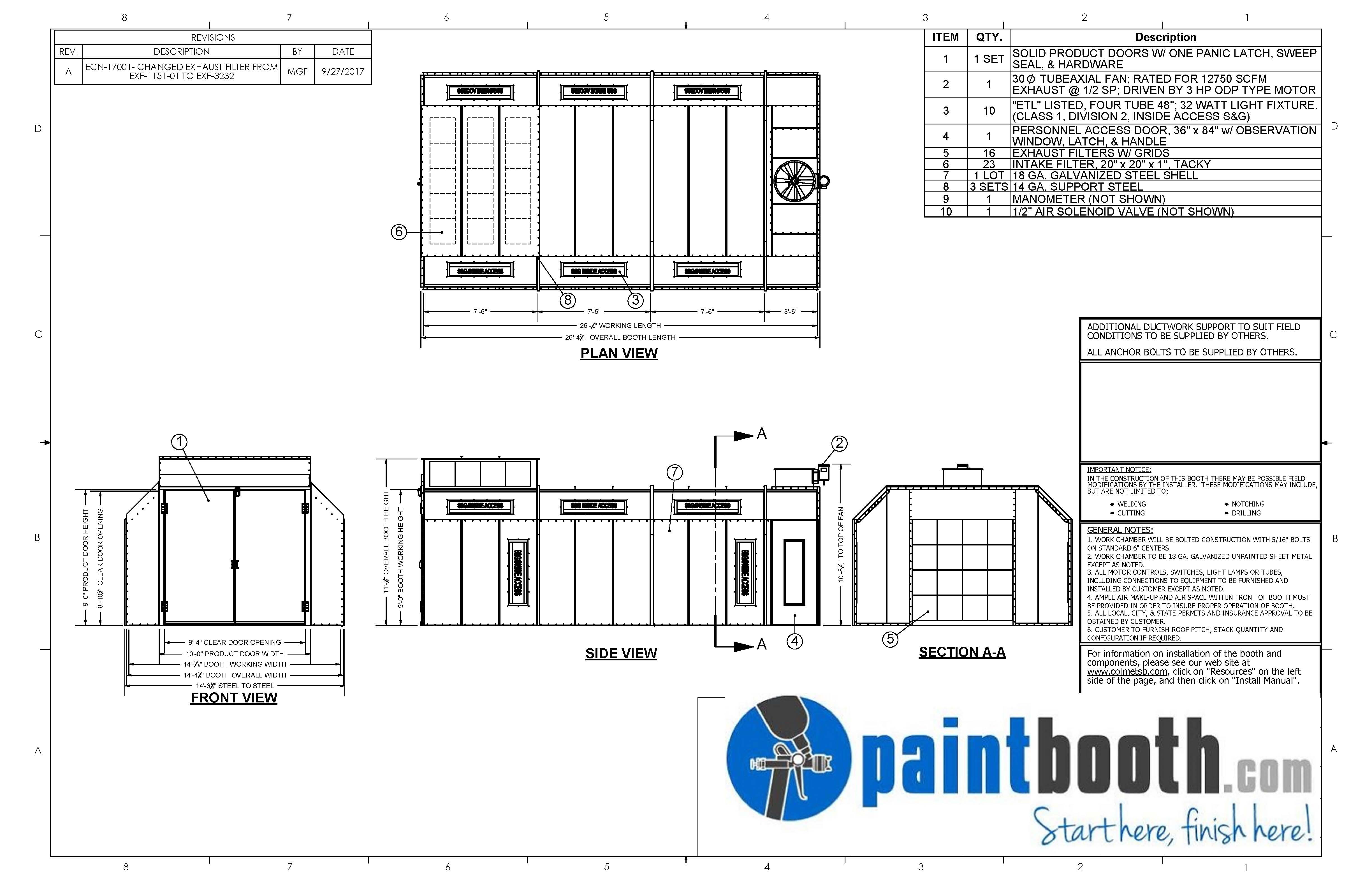

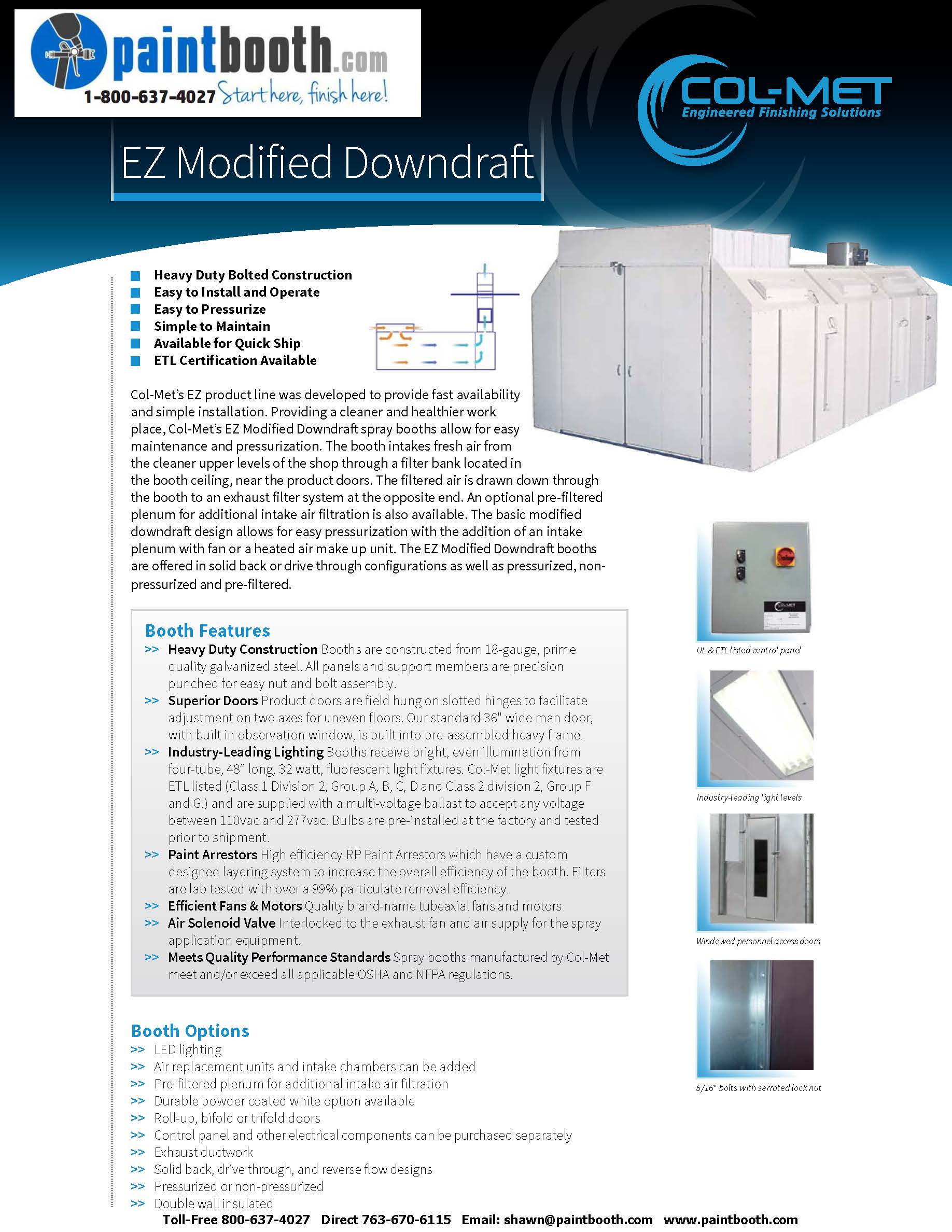

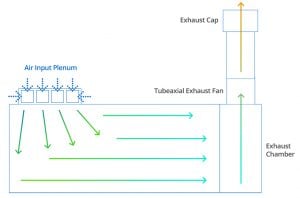

Our booths aid in providing a clean and healthy work place. Modified downdraft paint booths are not only easy to maintain, they can also be pressurized by ambient air or by a heated air make-up unit with a cure cycle. This style booth intakes fresh air from the cleaner upper levels of the shop through a secondary set of filters located in the plenum before entering the booth ceiling filters near the product doors. The filtered air is drawn down through the booth to an exhaust filter system at the opposite end of the booth.

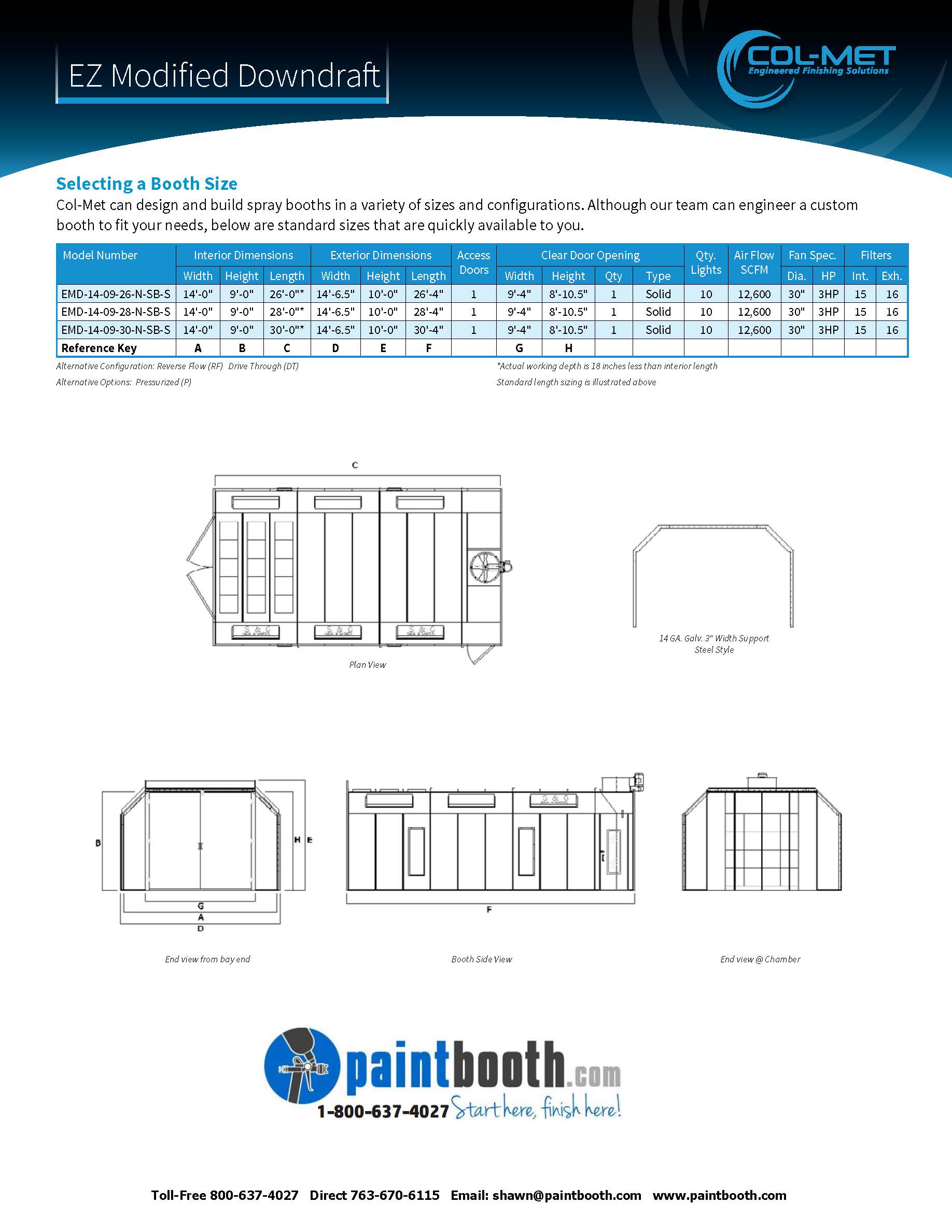

Our modified downdraft paint booth line is offered in a several standard sizes and configurations, which include pressurized, non-pressurized, solid back, reverse flow and drive thru designs.

Modified Downdraft Paint Booth Standard Features

Construction Boothsare constructed from 18-gauge, quality galvanized steel. All supports and panels are CNC punched for easy nut and bolt assembly.Product doorsare field hung on slotted hinges to aid in adjustment on two axes for uneven floors. Our standard 36″ wide personnel door has an observation window and is set into pre-assembled heavy duty frame.Booth Lightingcomes standard with 4-tube, 48″ long, 32-watt, fluorescent light fixtures. They are ETL listed (Class 1 Division 2) Inside Access and are supplied with multi voltage ballasts to accept any voltage between 120V and 277V power.Fans & Motorsare quality U.S. made brand-name tube-axial fans and motors.Air Solenoid ValveInterlocked to the exhaust fan and air supply for the spray application equipment.Performance Standardsmeet or exceed all applicable OSHA and NFPA regulations.ETL-Listedcontrol panels are options on many of our booths.

Modified Downdraft Paint Booth Drawings – click image to enlarge drawings

Our factory trained installation crew can get your new Modified Downdraft Paint Booth installed correctly and quickly.

This our specialty! You can rest assured that your new equipment will be operational in no time.

Need more information about Paint Booths?

Request a Quote

If you need help or have any questions you can always call 800-637-4027

The sizes listed below are standard catalog sizes. We can custom build all of our finishing equipment to meet your needs. Call us at 800-637-4027.

This booth intakes fresh air from the filtered front doors it. The air is pulled across the parts being painted to the exhaust filter bank located at th e rear of the booth. The air is then filtered and exhausted in through the duct work.

One of the most important details not to be overlooked in a paint booth is the lighting. Our booths feature industry superior lighting with four-tube, 48″ long, 32-watt, fluorescent light fixtures. They are ETL listed (Class 1 Division 2) inside access and are supplied with multi-voltage ballasts to accept any voltage between 120V and 277V power. Bulbs are included.

LED light fixtures are an option that can be easily integrated into any existing spray booth or fixture. To find out more about LED light fixtures, please click here.

Options

- Powder coated white inside & out

- Heated air replacement units

- Bi-fold, tri fold or roll up doors are available

- Control panel to operate the booth & connect other electrical options

- LED light fixtures

- Exhaust and intake ductwork

- Solid back or drive thru designs

- Pressurized or non-pressurized

- 2” Double wall insulated

Our products meet and/or exceed all applicable OSHA and NFPA regulations. They are also ETL- Listed with purchase of optional control panel or heated air make up unit, which comes standard with a control panel.