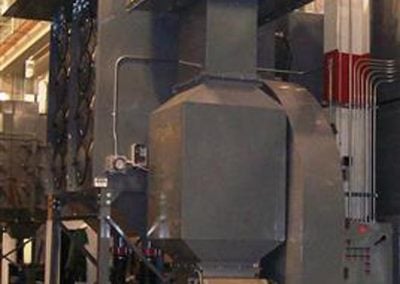

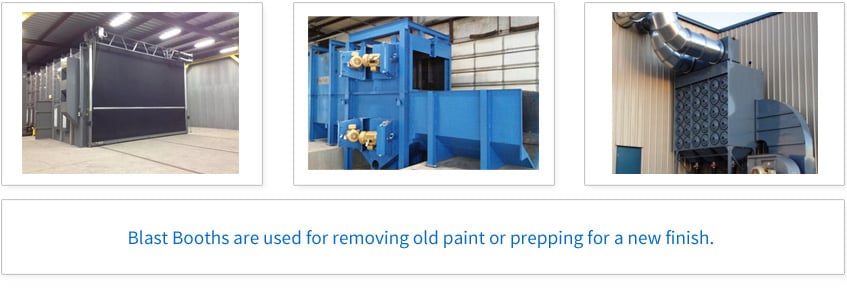

Sand Blasting Booths, Recovery Systems & Dust Collectors

Instead of utilizing harmful chemicals to strip paint, a sandblasting booth uses high pressure to propel abrasive materials on surfaces to remove paint, which is just as efficient yet keeps your workers safe from toxic substances. Our sandblast booths can be customized to meet your shop needs.

We guide you every step of the way: from consultation to design and implementation for an existing line or for brand new equipment. What’s great about a sandblast booth is it provides a balanced environment for surface treatment regardless of outdoor weather conditions

The sand blasting booths wall and roof panels are 10 gauge steel cut by a CNC plasma table. This method ensures the accuracy of all dimensions and bolt hole alignment. Aluminum seam caps are installed at each panel junction.

All our sandblast booths are equipped with fluorescent light fixtures. Wall lights are protected in 10 gauge housings behind ¼” thick Lexan blast covers. Silicone is provided as sealant for all light fixtures.

Entry and exit work doors are fabricated with heavy wall tubing and double lined with 10 gauge skins. All door exterior edges are sealed with heavy-duty rubber.

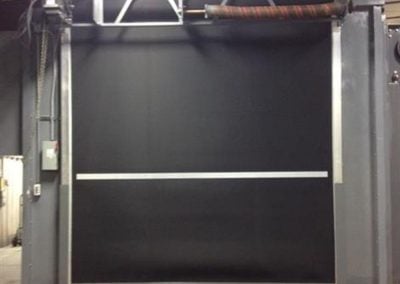

Rubber roll up doors can be requested. Doors are one solid sheet of ¼”

SBR curtain, allowing for smooth operation. Doors come with reversing edge and thru-beam photo switch safety features.

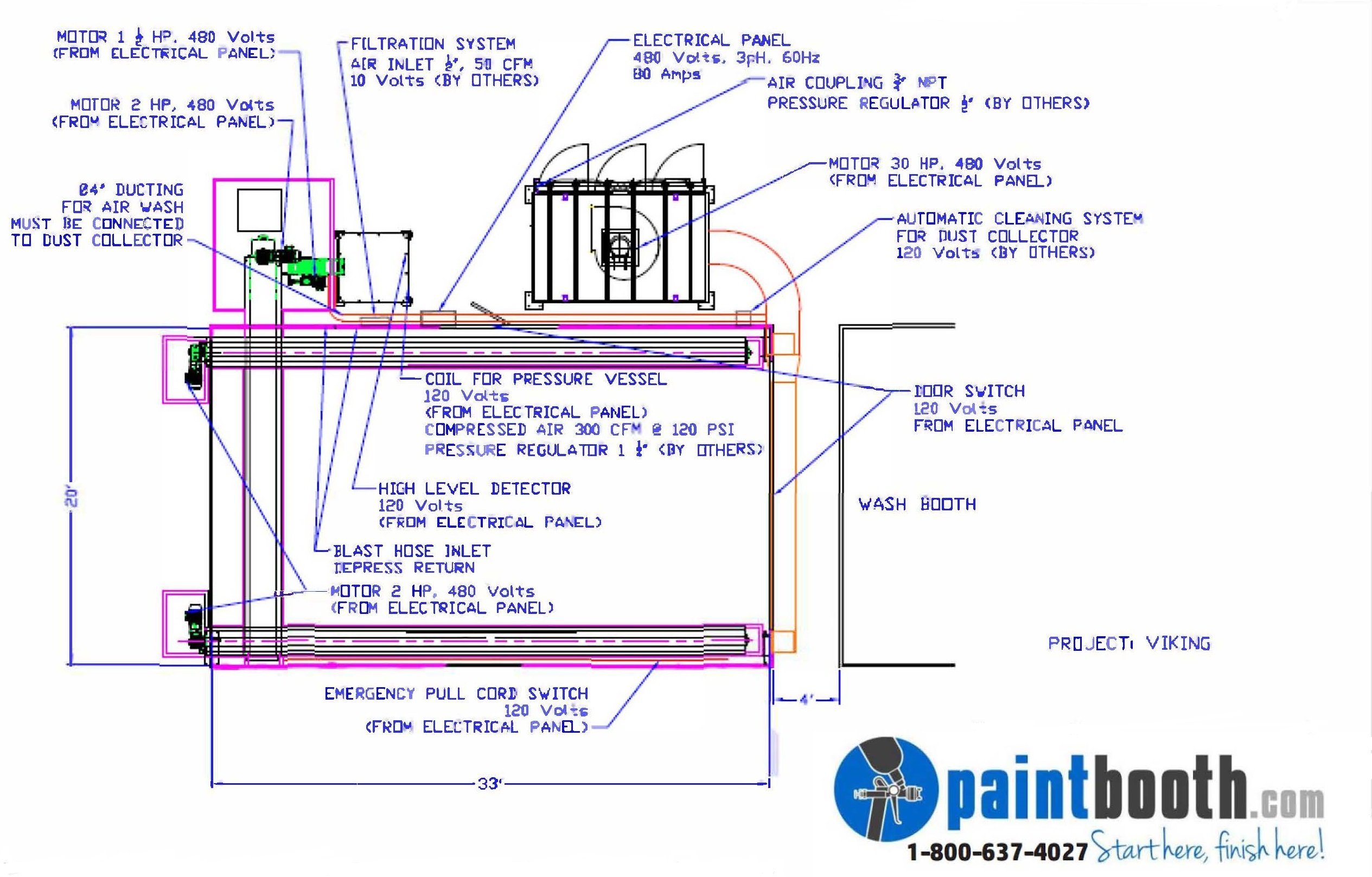

Dust Collection

Whether catching blast dust or torch table fumes, we have a collector for you. Our dust collectors are manufactured of 3/16” plate. We use the most common size of filters so most brands or types fit our systems.

We can provide after filters for dust collectors installed indoors. HEPA rated filters are used to ensure clean air is returned into your facility.

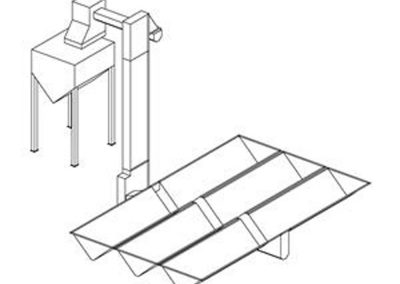

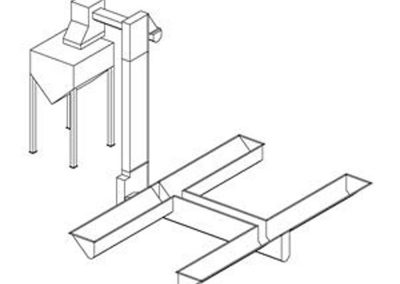

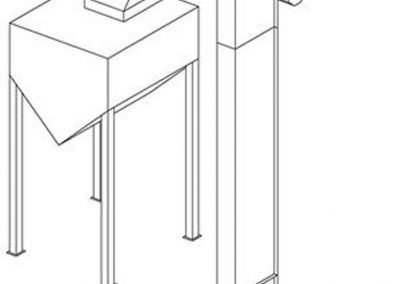

Reclaim Systems

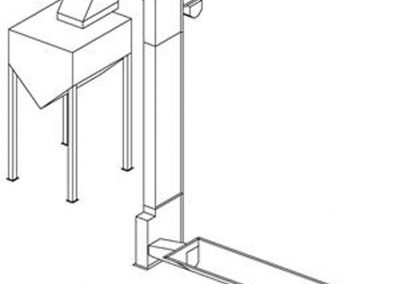

Reclaim or recovery systems allow abrasives such as steel grit, steel shot, aluminum oxide and glass bead to be reused multiple times saving the user time and money. We custom manufacture several types of reclaim systems for each customer’s specific situation: sweep-in or shovel-in systems, single auger systems, h-pit style systems and full floor recovery. You can end up recycling about 95 % of materials to greatly cut down on consumption costs.

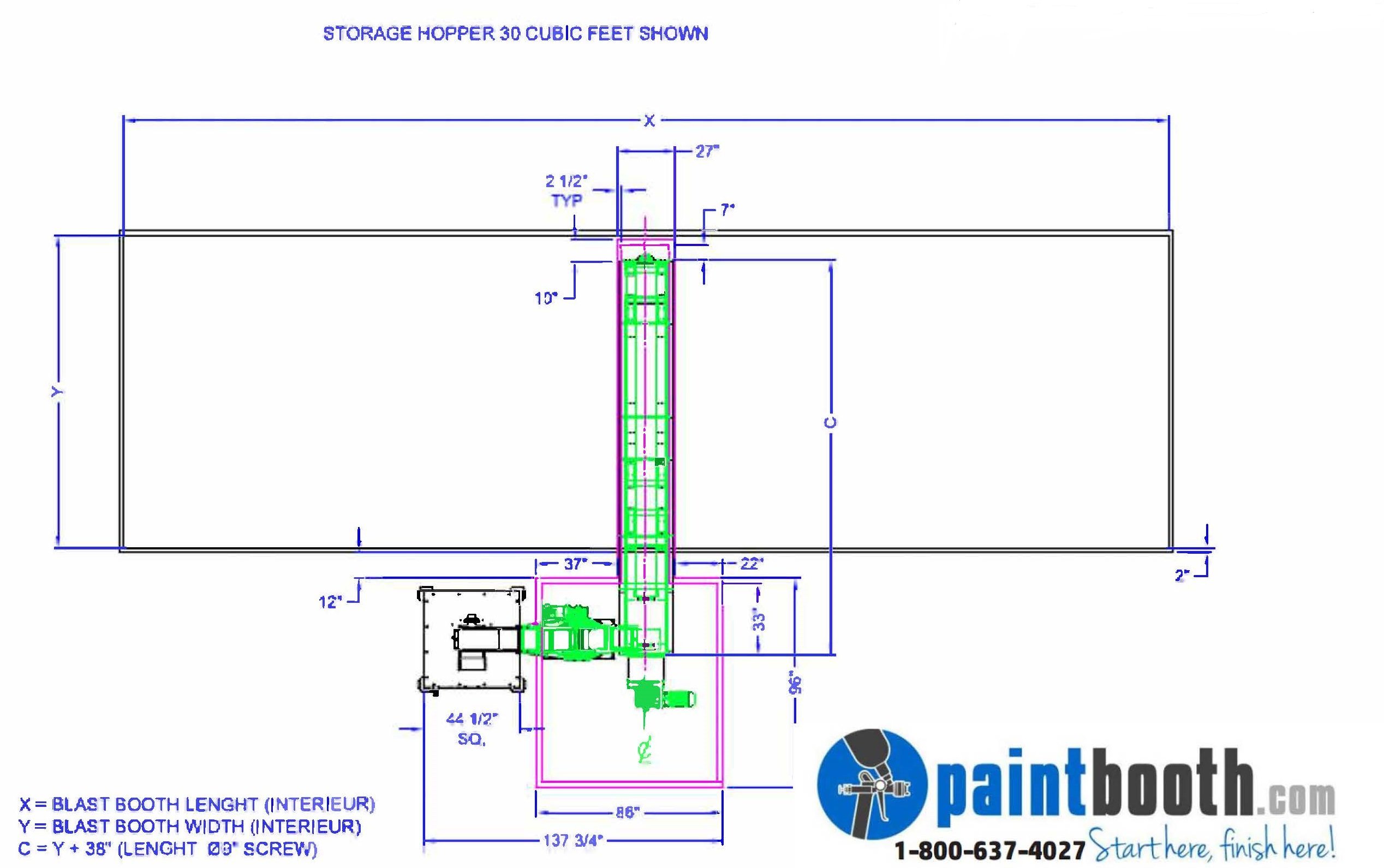

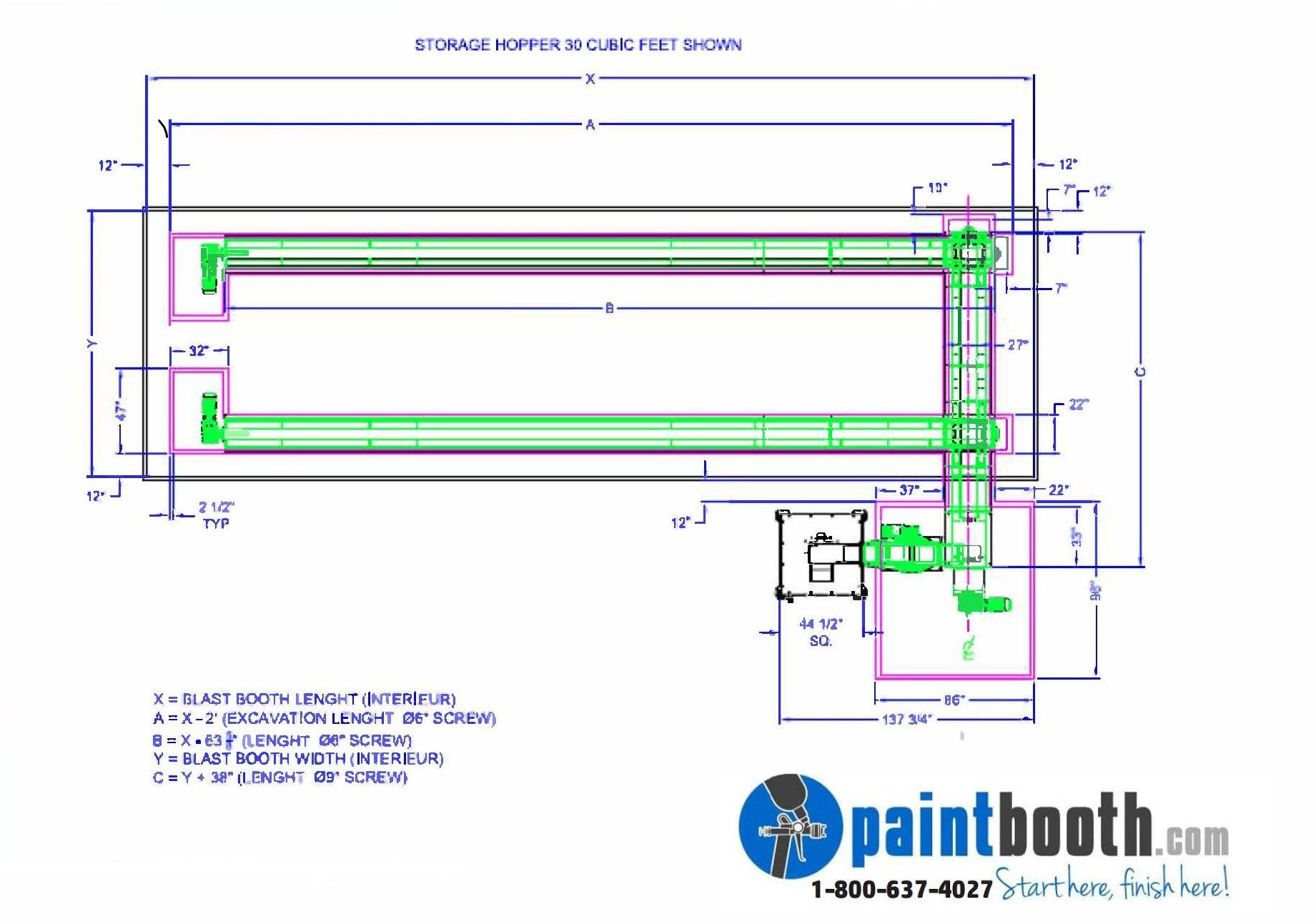

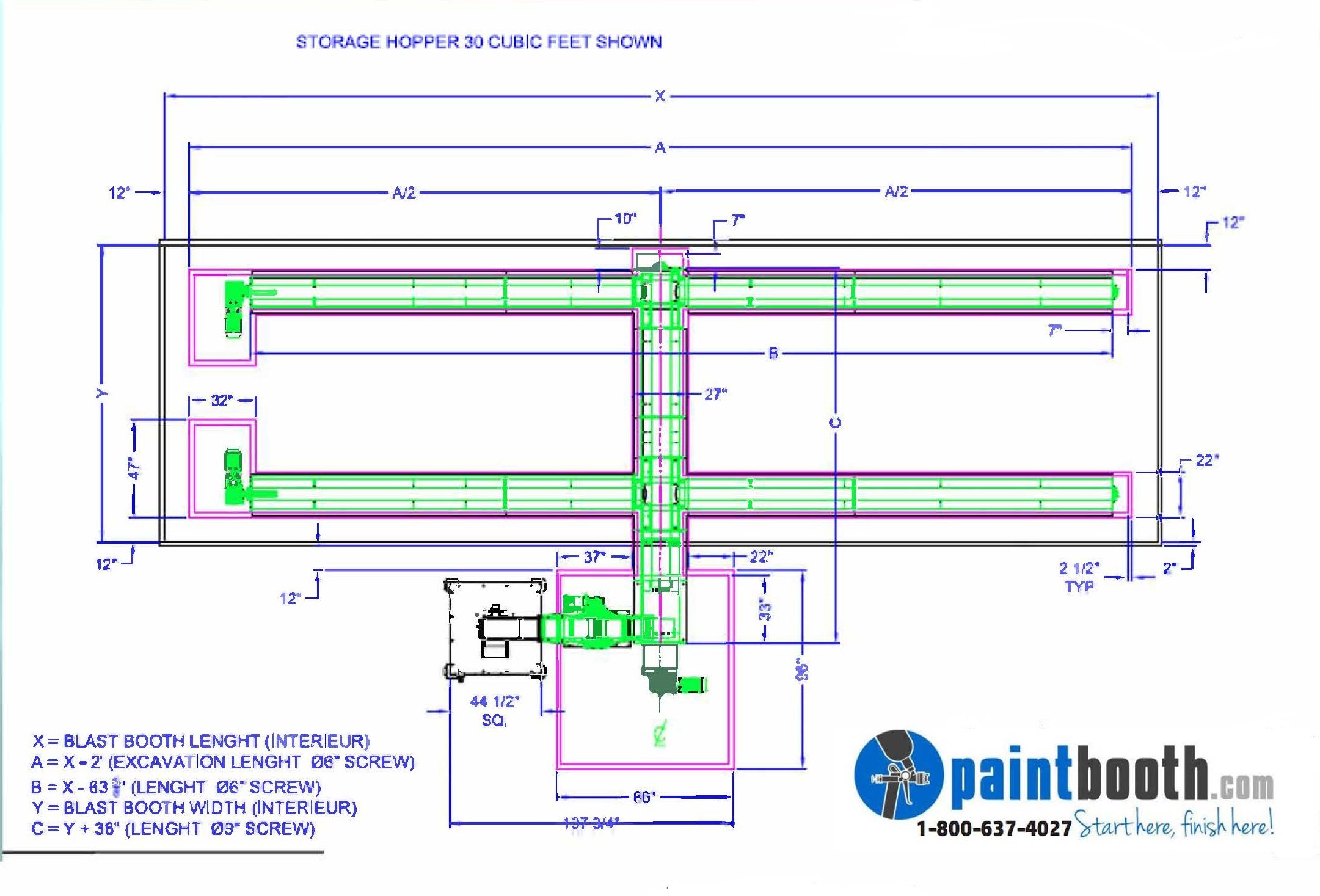

Booth Drawings – click image to enlarge drawings

Our factory trained installation crew can get your new Booth installed correctly and quickly.

This our specialty! You can rest assured that your new equipment will be operational in no time.