Powder Coating Ovens

No matter what you are looking to dry or cure we have got the solution for you, from standard size to custom size powder coating ovens.

We also build ovens with conveyor opening, raised floors, dual entry, rear heater boxes that can be roof mounted or floor mounted.

We offer a standard pre-fabricated line of powder coating ovens as well as the most advanced custom ovens available on the market today. Our equipment is built to last with hundreds of our ovens in the market today.

Here are just a few of the standards used in the construction of our powder coating ovens:

- Steel angle iron frames in all models

- 4″ & 6” insulated panel construction

- Tongue and groove wall panels to provide a leak-free seal

- 6# mineral wool insulation

- Aluminized steel construction

- 16-gauge aluminized steel ducting

- Explosion relief doors with FM approved latches

- State of the art eclipse burners available in natural gas or propane

- Floor track or overhead conveyor compatible

- Floor or roof mounted burner boxes

STANDARD CONTROLS

- NEMA 12 control pane

- Digital temperature controller

- 16-hour batch timer

- FM gas train

- Eclipse™ flame safety

- Main line disconnect

- Air proving switches for critical fans

- 230/460 V, 3 Ph., 60 Hz

- Red Lion high-temperature limit switch

- UL / CUL listed control panel

OPTIONAL PLC BASED CONTROLS ARE ALSO AVAILABLE

PLC Controls

PLC controls utilize the latest in touch-screen technology for minimum complexity and maximum flexibility. Smart touch uses a Programmable Logic Controller (PLC) to control the oven components and monitors. All our ovens comply with all applicable NEC, OSHA and NFPA regulations.

Controls include:

- Motor startersOverloads

- Gas pressure switches

- Oven temperature

- Burner box temperature

- Touch screen that includes a troubleshooting screen

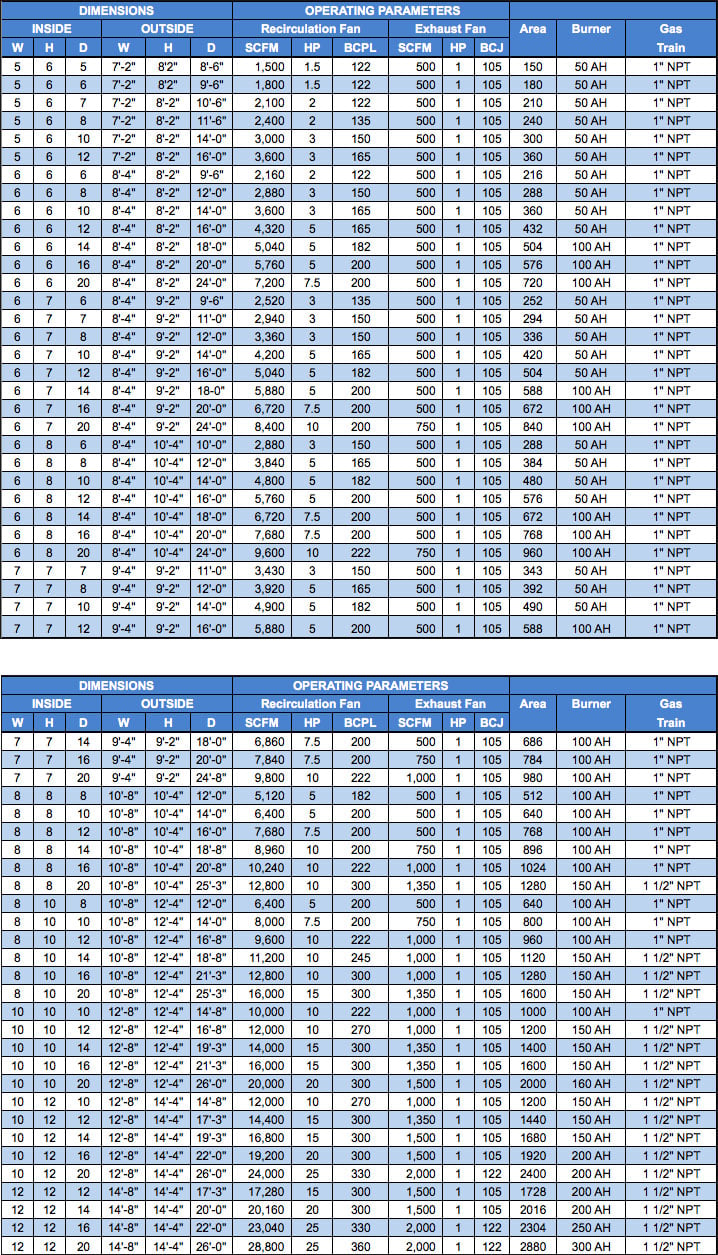

TECHNICAL DATA

- Interior dimensions are clear between ducts, walls, floor and top

- Allow a minimum of 6″ between parts and ducts for airflow

- Stack is not included with the oven but can be purchased as option

- Eclipse™ Version 2 air heat burners

- All specifications are subject to change without notice

- Larger ovens are shipped unassembled with factory tested recirculation units and assembled burners.

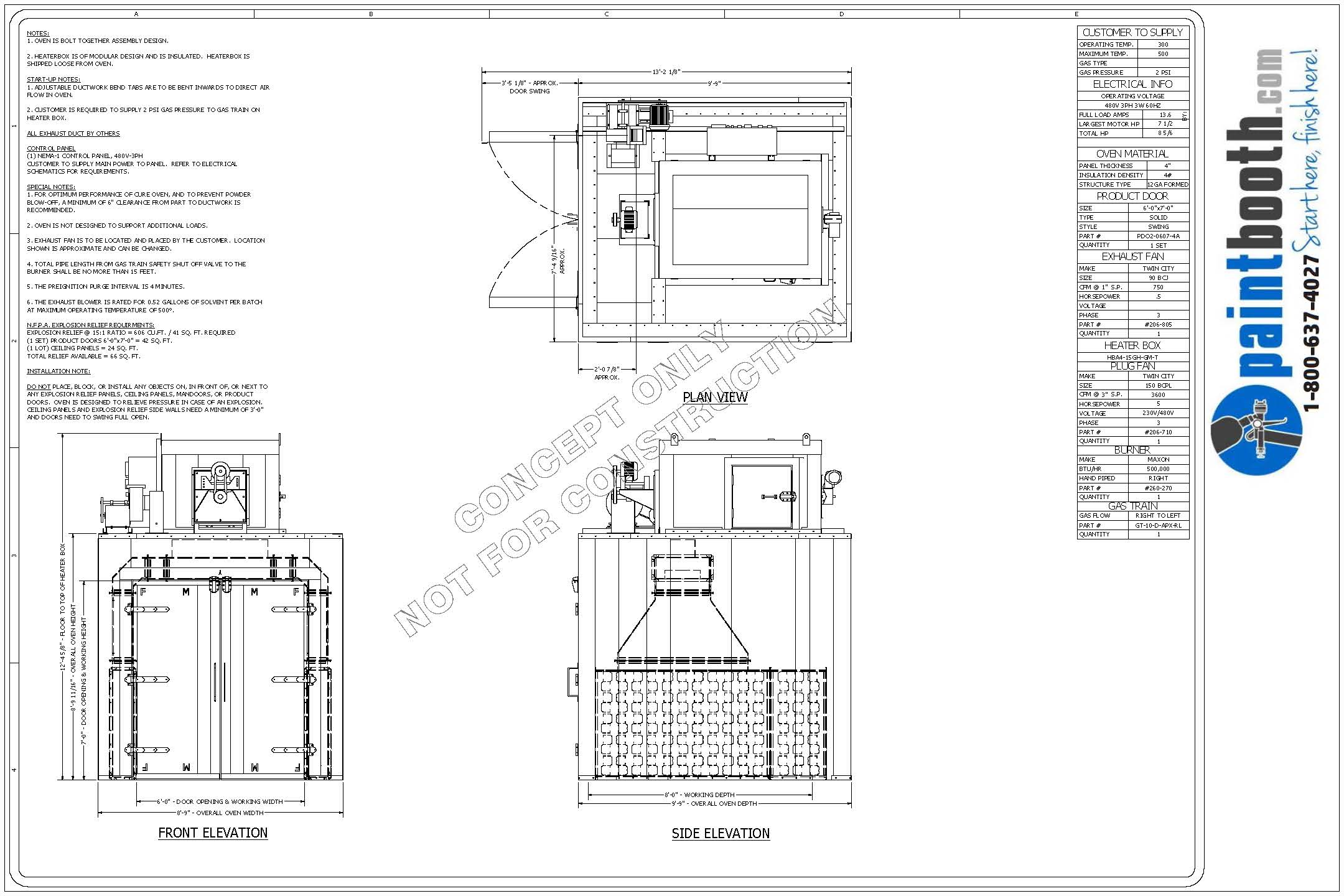

Example Powder Coating Oven Drawings – click image to enlarge drawings

Our factory trained installation crew can get your new Powder Coating Oven installed correctly and quickly.

This our specialty! You can rest assured that your new equipment will be operational in no time.

Need more information about Powder Coating Ovens? Request a Quote

If you need help or have any questions you can always call 800-637-4027

The sizes listed below are standard catalog sizes. We can custom build all of our finishing equipment to meet your needs. Call us at 800-637-4027.

Batch Oven Controls

Standard Control Panel Includes:

- 3 Phase main disconnect

- UL/CUL listed in a NEMA12 Enclosure

- Motor contractors and protectors

- Analog 1 second to 300 hour batch timer

- Digital temperature controller and high temperature limit with rollback protection

- FM approved gas train with high pressure, low pressure, and proof of closure safety switches. Includes vent less regulator and dual blocking valve. 2-5 psi recommended gas pressure

- Air proving switches for all critical fans

- Terminal strip to connect control panel to burner box

- UV scanner flame monitoring for reliable start-up

- 4230V/480V 3-phase 60Hz

Upgrade to a PLC Control Panel, which allow for simple and more efficient operation of your equipment.

- 6″ Touchscreen with four batch modes and troubleshooting capabilities

- 1 Second to 16 hour digital batch timer with countdown indication

- Digital self-tuning temperature controller and high temperature limit with rollback protection

- Control panel prewired to burner box, only field wiring needed is exhaust fan and communication between main panel and touchscreen

- Digital password protected purge timer for safer operation

- Available VFD control on exhaust fan for faster purge and cool-down times

- Digital chart recorder (additional costs apply)

Batch Oven Options

- Custom oven designs to meet any requirements

- Exhaust stack is not included and can be purchased as an option

- Plant assembled for easy installation

- 6″ Touchscreen with four batch modes and troubleshooting capabilities

- 1 Second to 16 hour digital batch timer with countdown indication

- Digital self-tuning temperature controller and high temperature limit with rollback protection

- Control panel prewired to burner box, only field wiring needed is exhaust fan and communication between main panel and touchscreen

- Digital password protected purge timer for safer operation

- Available VFD control on exhaust fan for faster purge and cool-down times

- Digital chart recorder (additional costs apply)